Quick Tip: Hone In On the Perfect Fit with a "Goldilocks Array"

Designing 3D-printed parts that need to perfectly match the dimensions of something else can be arduous, because it'll often mean meticulously designing-then-printing-then-trying each individual iteration, ad infinitum.

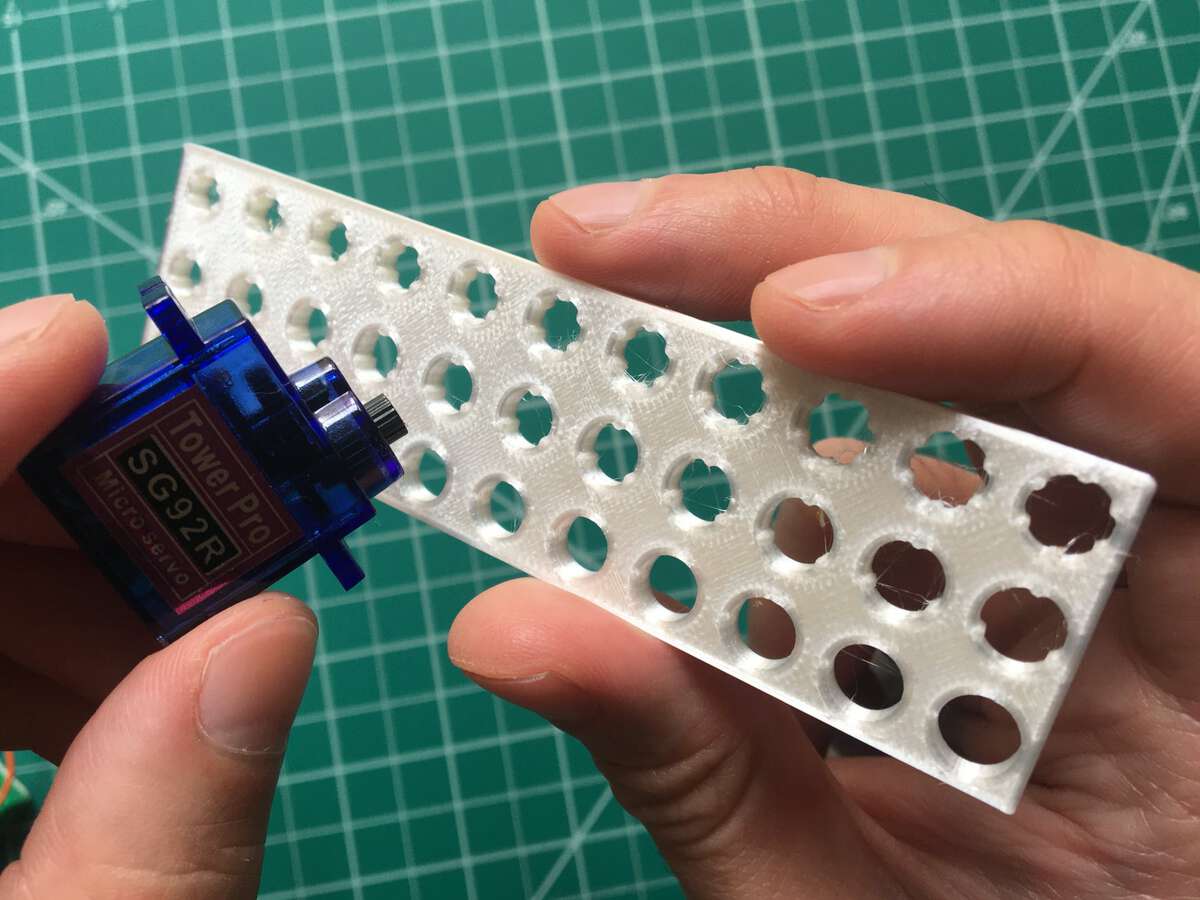

A trick I like (and I'm sure this is old news to many folks) is to combine an array of those tests into one big combo test. Then, just like Goldilocks, all you have to do is move your part around the array until you find the best fit.

The time gained in skipping the back-and-forth from your printer more than makes up for the extra time it spends being printed.

Example

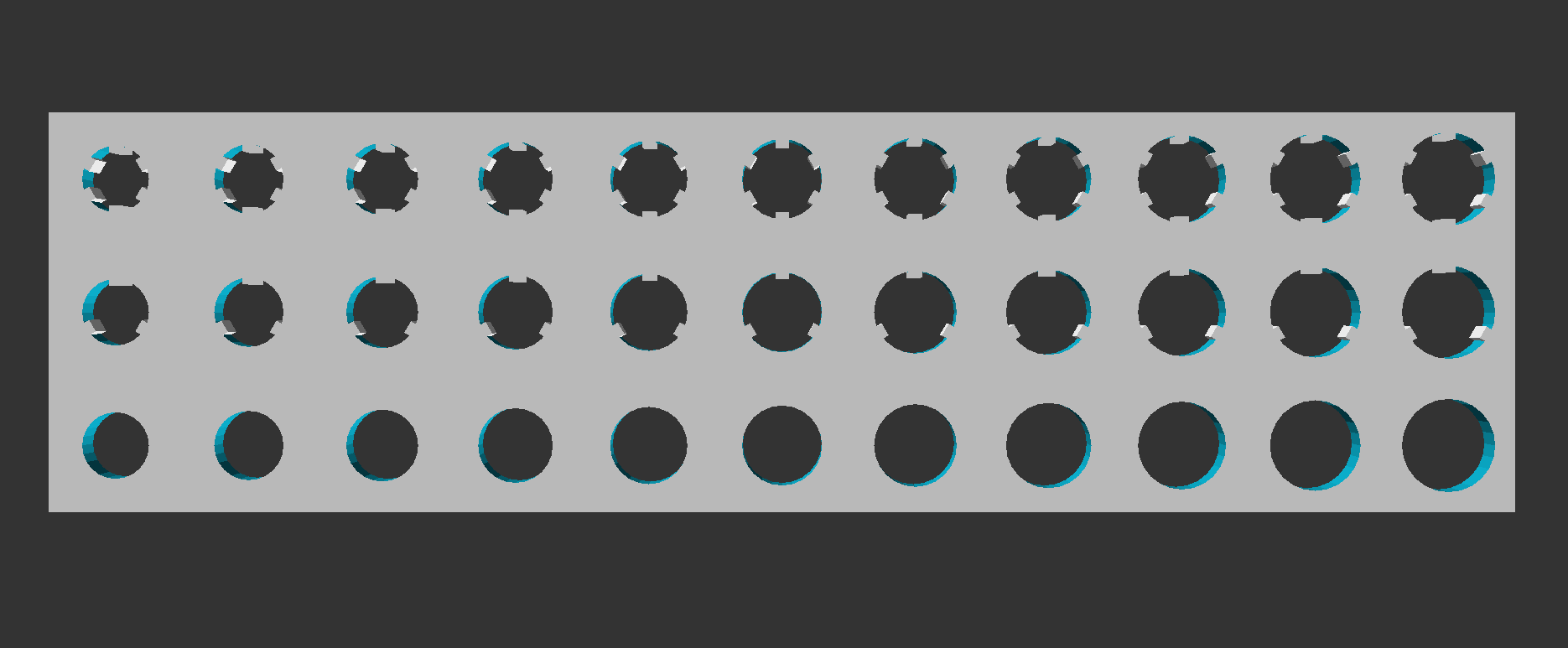

In the picture above, I'm designing a horn to for a servo shaft, and my "goldilocks array" has two axes: cavity diameter on the horizontal X axis and shim count (borrowed from my adventures in making potentiometer knobs) on the vertical Y axis.

Model

OpenSCAD Code

The concept is agnostic to implementation but I think is eloquent in code.