Quick Tip: Avoid 3D-Printed Supports with Sacrificial Bridge

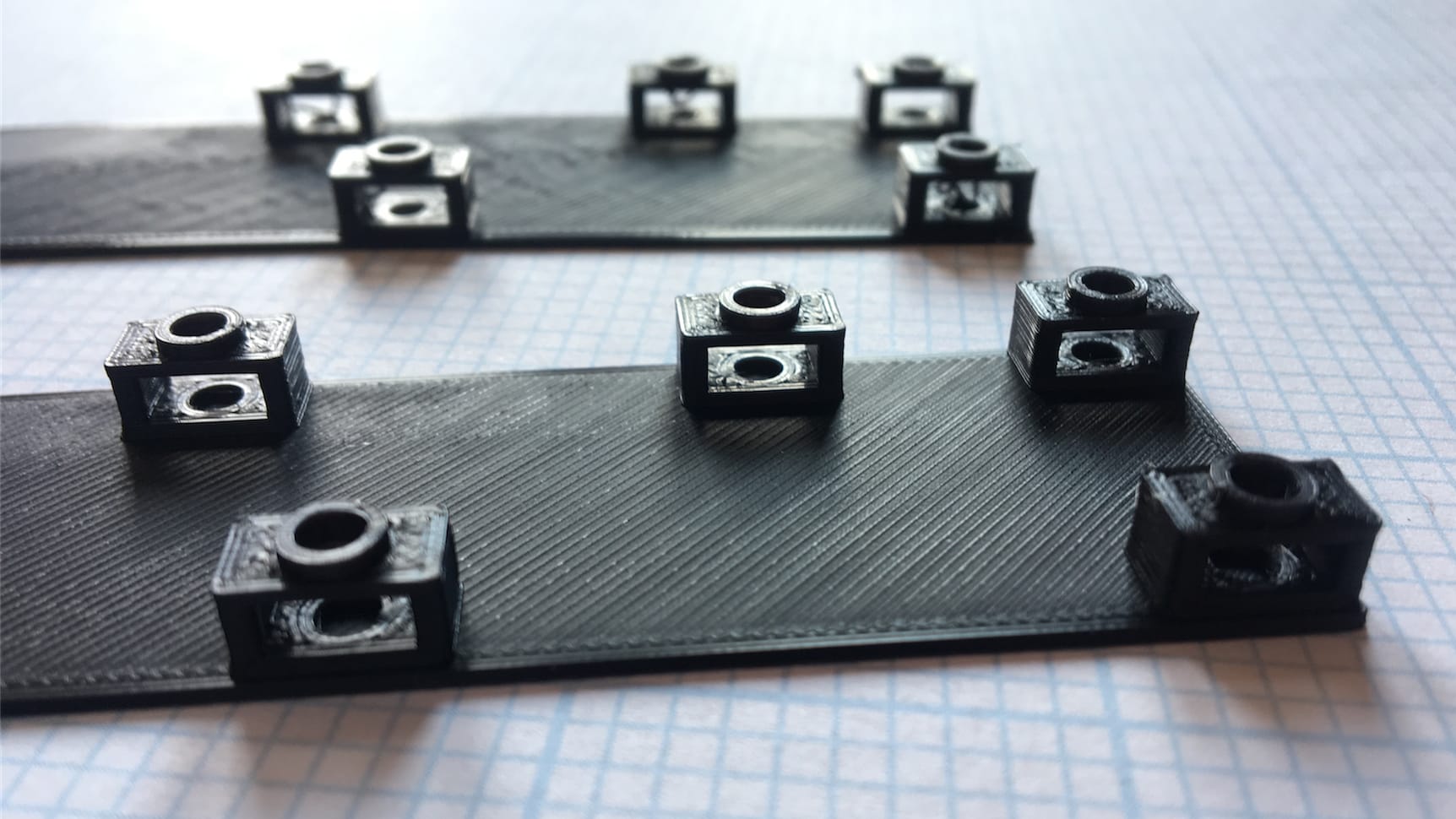

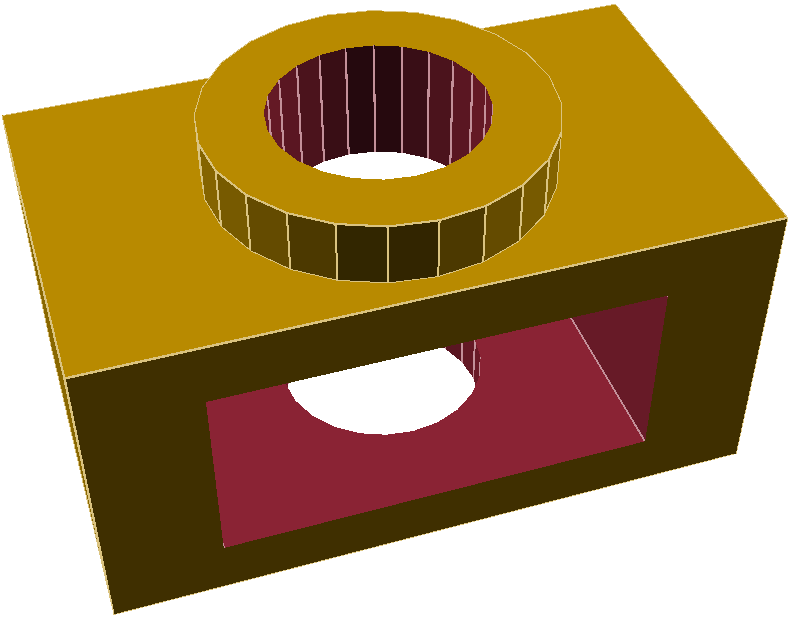

A lot of my designs have bridges with holes in them, like this post with a locking cavity for a hex nut:

If printed without supports, the material at the top of the cavity has nothing to sit on and falls inward if it does anything but go straight across. Not the end of the world, but really not ideal, especially for a part that needs to be perfectly calibrated.

And printing with supports can be counter-intuitively even messier, because the supports are hard to remove at such small dimensions and tight spaces.

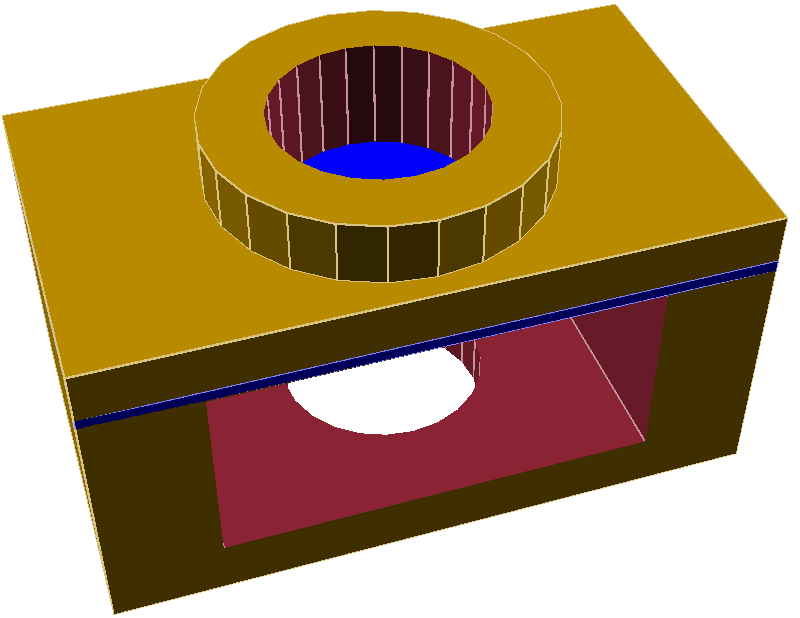

A cheap way to get the best of both worlds is to make your own support: a sacrificial, solid bridge over the cavity to ground the otherwise floating layers above. Here it is highlighted in red:

After printing, drill out the excess plastic or carefully melt it back with a hot soldering iron.

This process of designing for easier manufacturing is called, you guessed it, Design For Manufacturability or DFM for short. It can be a pretty dry subject for DIYers but there are some good articles in the right places.

Easy!